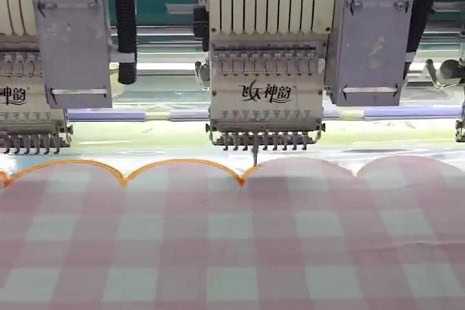

First of all, make sure the piece of cloth is embroider-ready, such as the printed scalloped tablecloth you’re seeing in the picture, we get to do the print and wash them ready, then cut the cloth into every piece with scalloped edge in advance. After the above procedures, put each piece on the platform flat and put a stabiliser underneath.

Let the stitches of the embroidery machine go through every inch of the edge carefully, and turn the cloth when it comes to next edge, the whole process would take over a few hours to make sure the edges would look perfectly thick without any dots. And because the extra fabrics have been cut away so the edge would be in a smooth and elegant way.

Last but not least, check everywhere on the edge to see any skipping stitch exists, although the machine is productive but make an inspection would be necessary. If the skips do exist, our craftsmen would use the threaded needle to make it up to ensure every space the customer see would be gorgeous.

No wonder the complex manufacturing process would end up in a high price but every penny you spend would be worth it!